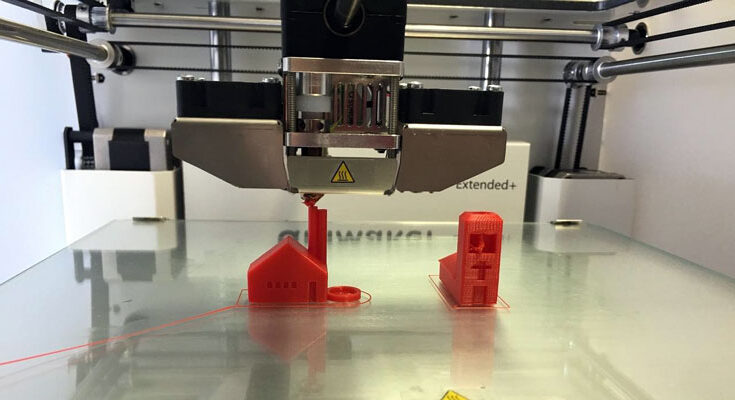

Germany’s Heidelberg IT data center was constructed using a 3D printer, producing less CO2 than traditional methods. This set a standard for future data centers and building projects worldwide. The initiative appeals to businesses to reconsider their approaches to future construction, focusing on sustainable development, cutting-edge technology, and innovative architecture.

The fast integration of 3D printing technology into the construction of the data center within 140 hours signified an unprecedented milestone within the construction industry. This creative way of building has tested standard building methods and shown how much time and resources can be saved. We’ve highlighted the benefits of implementing 3D printing tech in modern constructions.

Unique Construction and Design

The use of 3D printing technology during the data center’s construction ushered in several novel approaches to design and construction. With 3D printing, structures can be printed directly from digital models instead of traditional building methods that require human effort and the assembly of prefabricated components. By utilizing this technology, complex patterns were manufactured in ways that would be highly difficult, if attainable, using traditional methods.

Before being introduced into construction, 3D technology first appeared in computer programming, with many two-dimensional games being converted into 3D titles. This was predominant in the online casino industry, primarily dominated by classic fruity slots before the introduction of 3D video slots. In turn, the 3D video slots had a more significant appeal to newbies, as they came with demo games that allowed players to play for free and master skills to win money from slots. Their availability in several themes also contributed to their quick acceptance in the industry.

Speed and Efficacy

One of 3D printing’s most impressive features is its extraordinary speed and efficiency in construction. The fact that the data center was completed in just 140 hours demonstrates this. 3D printing can create complex geometries and bespoke components. This maximizes material utilization and improves the data center’s overall design. The ability to reproduce intricate designs and structures from digital files substantially diminishes the potential for error, thus ensuring proper time management.

By its continuous and automated operation, 3D printing eliminates the need for pauses or shifts during construction, substantially shortening the project’s overall duration. Similarly, 3D printing expedites construction, yielding more rapid outcomes than achievable through conventional means.

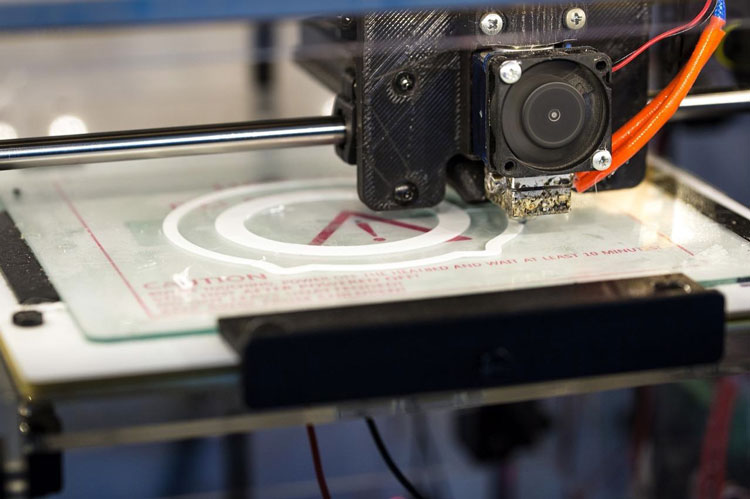

Future Potential and Sustainability

Using 3D printing to build a data center in 140 hours is a big step toward a greener future in the technology and building industries. This accomplishment illustrates the transformative capacity of 3D printing technology in data center construction and design.

It promotes creating a future in which structures are erected with increased speed and efficiency and a profound regard for environmental consciousness and sustainability.

The remarkable capabilities of this new approach have been demonstrated with the construction of the Heidelberg IT data center. While conserving time and resources, 3D printing brings into reality intricate structures and designs that may seem unattainable. This accomplishment introduces a novel construction speed, efficiency, and sustainability benchmark which are core elements of the construction industry.