Active voltage machines play a crucial role in ensuring the reliability and stability of electrical systems. With the increasing complexity of modern electrical demands, the relevance of voltage conditioning becomes paramount. This guide aims to explore active voltage machines, their functionalities, and their applications in various industries. Understanding how these machines work enables users to optimize their electrical systems, ensuring a steady supply of quality power.

What are Active Voltage Machines?

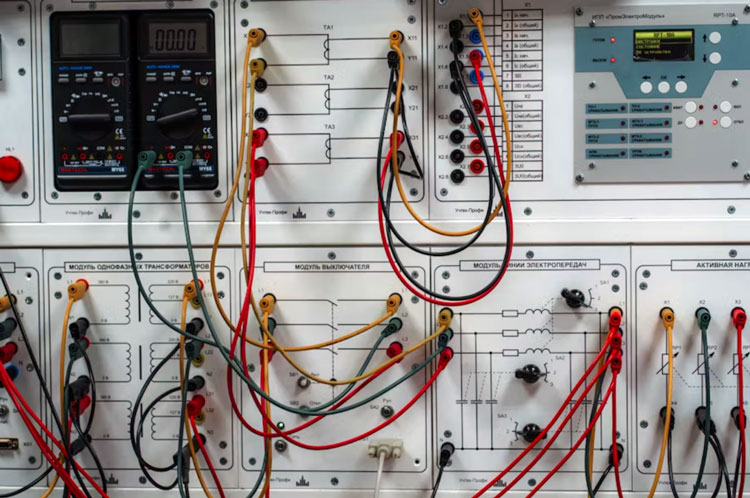

Active voltage machines are devices designed to monitor, regulate, and maintain voltage levels within electrical systems. Unlike passive voltage devices, which merely absorb surges, these machines actively adjust voltage parameters in real-time. They are essential for protecting sensitive equipment from distortions and fluctuations. The use of advanced electronics makes them suitable for handling wider voltage ranges and more complex patterns of energy consumption. One significant advantage is their ability to provide instantaneous corrections to electrical fluctuations. This is particularly important in facilities with a high concentration of sensitive electronic devices.

Data centers rely heavily on active voltage machines to prevent power interruptions caused by voltage drops or spikes. By connecting devices like active voltage conditioners, one can achieve an optimal power supply. These machines often feature intuitive interfaces for monitoring performance metrics, making it easier to manage energy distribution. They also support remote access capabilities, allowing for monitoring from various locations. This versatility contributes to their growing adoption in various fields, including manufacturing, telecommunications, and healthcare.

How Do Active Voltage Machines Work?

The operation of active voltage machines is based on the principle of real-time voltage assessment. These machines use sensors to measure the incoming voltage supply, instantly detecting any discrepancies. When an imbalance is detected, the machine activates compensating mechanisms to adjust the output voltage. One key operation method involves the use of feedback loops, where continuous monitoring allows for immediate adjustments to voltage levels. This ensures that any fluctuations caused by varying load demands, such as motors or high-power machinery, do not adversely affect the overall system stability.

With the use of specialized algorithms, these machines predict potential voltage issues before they arise, acting decisively to maintain the necessary levels. They stand out by filtering out harmonic disturbances, thereby contributing to cleaner energy. This process improves the overall efficiency of the electrical system and prolongs the lifespan of connected devices.

Benefits of Using Active Voltage Machines

The benefits of implementing active voltage machines within an electrical system are extensive. Primarily, they enhance the reliability of the power supply, reducing the risk of outages and prolonging equipment lifespan. This leads to a significant decrease in operational costs, which is vital for businesses that rely on continuous power. Another advantage is their contribution to energy efficiency. By ensuring optimal voltage levels, these machines minimize energy waste caused by malfunctions or inefficiencies.

This can have a positive impact on energy consumption, leading to lower utility bills and a more sustainable operational model. Active voltage machines can also improve power quality, which is becoming increasingly important as more devices are interconnected. High-quality power reduces electromagnetic interference, which enhances the performance of sensitive instruments. Reliability is further ensured through features such as automatic restart and diagnostic capabilities, allowing users to address any issues in real-time.

Applications in Various Industries

Active voltage machines find applications across a wide range of industries. In healthcare, maintaining g stable power supply is crucial for medical equipment functioning. Any disruption can lead to severe consequences; hence, active voltage machines ensure that devices such as MRI machines and life support systems operate within safe voltage parameters. Manufacturing industries benefit from the precision these machines offer. Many processes depend on the stability of voltage for motors and automated systems. Fluctuations can diminish product quality or hinder overall productivity.

As a result, industries with robotic systems or CNC machines heavily invest in these solutions for optimization. Data centers are another segment where these machines play a pivotal role. Technologies that power the digital landscape require an unwavering power supply, as slight variations can lead to catastrophic data loss. The ability to maintain appropriate voltage levels lends great reliability to operations, essential for continuous data flow.

Choosing the Right Active Voltage Machine

Selecting the appropriate active voltage machine involves several critical considerations. First, it’s essential to assess the specific needs of the electrical system in terms of voltage levels and load types. Each machine comes with different specifications, so understanding these parameters ensures a suitable match for your requirements. Evaluating features such as response time, energy efficiency, and compatibility with existing infrastructure is vital. A machine that can handle momentary spikes and extended voltage sinks with swift responsiveness will better serve the system’s health.

Customer support and service agreements should also be factored into the decision, as ongoing maintenance is crucial for optimal performance. Lastly, companies should consider the scalability of the active voltage machines, allowing them to adapt to future energy demands. By investing in machines that can evolve with your operational needs, businesses can sustain performance without incurring additional costs from unnecessary upgrades.

Maintenance and Care for Active Voltage Machines

Proper maintenance of active voltage machines ensures their longevity and optimal performance. Regular inspection of components, including filters and sensors, prevents malfunctions. Scheduled checks contribute greatly to identifying potential issues before they escalate into larger, costlier problems.

Cleaning and upkeep should be part of routine schedules, as debris or dirt can impact sensor functionality. Most manufacturers provide guidelines on maintenance frequencies and necessary actions, and adhering to these instructions enhances machine efficiency over time. Maintaining an accurate record of performance metrics and possible faults can aid in diagnosing historical trends. Using this information, organizations can help to establish effective maintenance schedules and prioritize machine upgrades or replacements.

In conclusion, understanding and implementing active voltage machines can significantly enhance the reliability and quality of electrical systems in various settings. From healthcare to manufacturing, these machines provide essential support in maintaining voltage stability. By investing in the right equipment and ensuring proper upkeep, users can optimize their energy consumption, extend the lifespan of their devices, and save on operational costs.